Canton Glass Company

Contents

Canton Glass No. 1

Early Production

Production began in 1883 on 235 Marion Street in Canton, Ohio. Some minor problematic situations hindered immediate production. These issues were set as top priority and were worked out in a reasonable of an amount of time. The company published their first advertisement on June 7, 1883 in Crockery & Glass Journal publicizing their Pressed, Brown, Cut and Engraved Table Glassware, Specie French and Solid Ring Jars, Bar Goods, and Lantern Chimneys. (APPENDIX A). Production was finally started on October 18, 1883 and was employing over 200 men, boys and girls (Sanford 2). The company was producing enough wares to keep it running through the remainder of the year and for many years to follow. In addition to glassware, they also manufactured opal nest eggs, mortars and pestles, the Canton Domestic Fruit Jar with wire clasp and glass lid in clear and cobalt, and the patented Ripped Filtering Funnel (Grant County). (APPENDIX B). The Table Glassware could be bought in a couple designs. The choices were the Number 10 (Primrose), the “Barred For-get-me-not,” and the “Dewdrop (Sanford 2).”Reconstruction

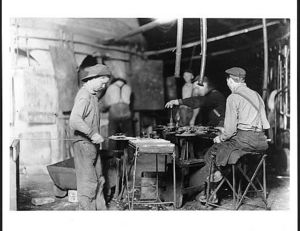

Tragedy struck the Canton, Ohio plant in 1892. A glass company’s worst nightmare came to life. A terrible fire destroyed the Canton Glass Factory. Their plant was destroyed but they managed to salvage portions of their molds. Since the molds were still in working condition, the management decided to move to an existing plant at Beaver Falls, PA instead of rebuilding right away. In fact, when they decided to rebuild, the board chose to relocate altogether. Marion, Indiana was the optimal choice due to the city’s plentiful natural gas collection. The plan for the factory was published in China, Glass and Lamps on December 17, 1890 and were as follow: it would be located on the 1800 block of Spencer Avenue, there would be the main building consisting of an 80’x 164’ main room, a 12’ x 12’ shipping room, a 20’ x 30’ packing room, a 24’ x 40’ blacksmith shop, and a 40’ x 100’ machine shop with a mold room and grinding/polishing room. There was a 15-pot furnace in the main room. Also in the proposition but never built were a 20’ x 50’ cooper shop and a 250-barrel water tank. Another innovation at the Marion plant was its corrugated iron structure of the buildings and its steel roofs (Iwen 21-2)(APPENDIX C).

New Workforce

There was a newly remodeled staff at the Canton Glass now. There was Henry W. Harter, the president; Charles J. Bockius, the secretary and treasure; Charles H. Henderson, the superintendent; and the previous David Barker, the designer. (APPENDIX D). This new location came with a new variety of products. They produced new tableware, lamps, knob pulls, tumblers, lantern globes, bird cups, birdbaths, decanters, beer mugs, percolator tops, druggist goods, mortars and pestles, fish globes, roofing tiles, candy jars, Canton Domestic Fruit Jar, and the patented Ribbed Filtering Funnel (Iwen 20)(APPENDIX E). Most of these they proudly would promote in their extensive letterheads. (APPENDIX F). Another notable product that was manufactured there was the infant glass coffin weighing any where between 42 and 60 pounds and was blown by James Cline (Iwen 21).

Prosperous Production

Business was booming at the Marion plant. In late August, the company’s 150 employees were turning out 125 barrels of wares everyday resulting in incredible revenue. The employees and their families were also a positive economic and demographic accessory increasing Marion’s population by over 300 people (APPENDIX G). Two-thirds of the laborers were skilled and receiving pay ranging from $3 to $8 per day. Each week had a payroll of approximately $1300. Like every business would, Canton took advantage of any cost-cutting opportunities that presented themselves. A prime example of this was their sand ordering which was a crucial ingredient in making glass. They originally ordered sand from a company west of Chicago in Millington, Illinois. The recipe for the sand compound was a 3 to 1 ratio of sand to soda ash. Quoted in the Marion Chronicle issue on January 1, 1892, “Nitrate of soda is used as a purifier and arsenic s a bleacher. The green is killed by the arsenic and manganese, and the yellow is killed by cobalt blue. (GCD 21). Luckily for Canton, a large sand deposit, estimated to contain nearly 15 million tons of white sand, was found in the nearer Terre Haute, Indiana. The company shipped a ton of its sand to Canton where it melted quicker than sand used before setting a record time in three hours. Charles Henderson estimated the new sand would half the cost of sand purchased.Canton Glass Company was unusually fortunate during the early years of the twentieth century. The businesses crème de la crème meeting of demands of customers and their vast variety of products proved to be the premier combination for success.

Hamilton's Hardknocks

Mild tragedy struck for the Indiana business in September 1894. The company’s superintendent, Sanford Hamilton, was on a business excursion when a train struck his carriage. The accident killed his horse and fatally wounded the latter but Hamilton walked away with minor, yet painful injuries. By October 10, he was nearly back to work and ready to begin his business traveling again. He sold many orders to companies all across the United States. In the September 9, 1892 edition of Marion Chronicle it was stated the Canton had so many orders for their products that the company simply could not fill due to not having enough man capacity to fulfill such a task. The company responded to the acclaims by enlarging land from the Marion Real Estate Addition to 41 additional lots selling for $200 a piece. This added a second 15-pot furnace, four new lehrs, and an increase in the work force from 150 to 235. Canton’s glass was so precise that it won the California Mid-winter Exposition in San Francisco, in 1894.

A Nearing End

The industry was becoming more and more uncertain and indefinitely workers fears grew. Their worst fear came to life on May 3, 1902, when National announced it would close the Canton factory. Manager James Bockius claimed it would move to Cambridge, Ohio, and indeed some of the equipment was moved to a plant there. Unfortunately one furnace shut down the very day it opened and then the next on July 1. Nearly 300 workers found themselves out of work. Many found new jobs in Jeannette, Pennsylvania while others went to nearby Greentown, Indiana. The empty plant remained abandoned in Marion for several years until in 1908 when David Lloyd, from Pittsburg, PA, bought the plant from the NGC for $55,000. The plant was converted to the Roberds Manufacturing Company and began producing wallboard. Most would consider this conversion as the end of Canton’s reign forever, but the determination and committed demeanor of the city of Marion would help Canton rise again.

Canton Glass No. 2

It was on July 15, 1902 that marked a new milestone in Canton Glass history. Glassworkers and the people of the town gathered to discuss the construction of a new factory. Marion Real Estate Company offered a site for the new plant, which happened to ironically be located directly across the street from previous Canton Glass No. 1 plant (Iwen 73). With a new plant came new funding requirements. Leo Nussbaum was the answer to where to find the balance necessary to start the business. The new Canton Glass No. 2 produced the same wares as the prior Canton No. 1. The new Canton began to thrive and a legacy seems to be pursued. It had revolutionary technology. A 16-pot furnace, instead of a 15-pot, melted 16 tons of glass in a one-day period. In December of 1909, Canton’s night and day shifts were hailed as Marion’s most substantial enterprises. The company once again had more orders than they could fill, so many that the worker’s only received Christmas and New Year’s Day off (Iwen 75).Berthold M. Nussbaum, Leo’s son, died on December 1, 1945 and with this came a shift in control on the Canton Company. Earl Kightlinger became president with William M. Wright as vice president, and J.D. Wright as secretary. A few years after William Wright became president. In March of 1958, he moved the Canton plant to Hartford City to the former Sneath Glass Company (Iwen 79). In 1971 Glass Factory Directory listed the company as David Lilly and Company, Inc; and had F.R. Hodges as president. It still remains listed respectively the same today. No glass is being made in the plant today but an office still remains open. All that remains of the famous Canton factories in Marion is nothing more than part of a Canton No. 2’s ware shed. (APPENDIX I). Without a doubt it can be said that Canton Glass Company helped lay a foundation and shape our glorious city.

References

- Grant County and Who's Who.

- Iwen, Marg. "Canton: the Glass Comany That Refused to Die! Part I." Glass Collectors Digest 01 Jan. 1999: 18-27.

- Iwen, Marg. "Canton: the Glass Company That Refused to Die! Part II." Glass Collectors Digest 01 Mar. 1999: 73-82.

- Johnston, Joyce J. "David Barker's Elephant Pattern Glass." Glass Collectors Digest 01 Sept. 1987: 58-69.

- Paul, F.L. Letter to Board of Directors of the Marion Federated Welfare Assn.. 15 Nov. 1922. Glass and Glass Manufactures. Marion Public Library, Marion.

- "Price of Canton Works." China, Glass, and Lamps 21 June 1902: 3.

- Roller, Dick. Indiana Glass Factory List. Grant Co. Marion, 1976.

- Sanford, Jo. The Canton Glass Co. DeLeon Springs, FL: Researched Glass Facts, 1998. 1-31.

- "The Canton Glass Company." Advertisement. China, Glass and Lamps 16 Dec. 1891.

Credits

This article was written by Mike Raabe and submitted on June 4, 2007 for Mr. Munn's ACP US History Class at Marion High School.